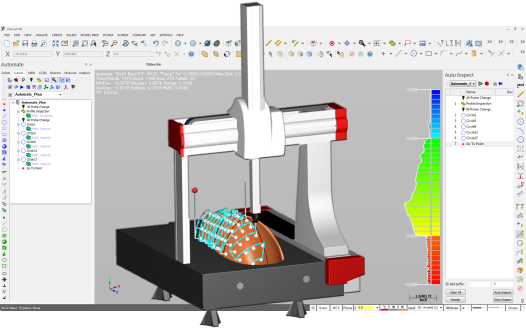

Manual CMM

Manual CMM with half-gantry’ bridge design has X and Y axis at the same level providing increased rigidity and offering an outstanding metrology platform for high accuracy small and medium part inspection.

The open structure BENCHMARK provides outstanding ergonomics and is ideal for the inspection of high volume production parts or single part inspection in the smaller manufacturing operations; its compact size is ideal for quality room or production CMM applications.

- Ultra rigid advanced alloy CMM platform provides maximum stiffness.

- Rapid thermal diffusion by advanced alloy CMM frame when temperature conditions change

- FEA designed provides optimum moment of inertia and minimum deflection at high accelerations

- One piece granite base plate with M8 threaded table inserts in generous grid pattern

- Rigid air bearings to all axes with wide bearing spread ratios

- Pneumatic Z axis counter balance

- 0.1 micron resolution measuring scales with dynamic signal processing

- Passive vibration damping system isolates external vibrations

- Open access to CMM measuring area

Measuring Strokes (mm)

Model X Y Z

5.4.4 500 400 440

6.5.4 600 500 440

- Optional touch screen computer for enhanced user ergonomics

- Optional wireless thermal compensation for shop applications

- Field upgradeable to full CNC programmable CMM

- Full digital motion control with probe path blending for optimized CMM performance

- Zero hysteresis friction drives to all axes

- Maximum Positioning Speed 517mm/sec

- Maximum Acceleration 1730mm/sec2